|

We sell and maintain office printers in West Sussex, East Sussex & Surrey the following areas:-

|

|

|

Printer repair:-

- Arundel,

- Billingshurst,

- Brighton,

- Burgess Hill,

- Caterham,

- Cheam,

- Chipstead,

- Crawley,

| Printer repair:-

- Charlwood,

- Copthorne,

- Cowfold,

- Cranleigh,

- Dorking,

- East Grinstead,

- Edenbridge,

- Ewell,

| Printer repair:-

- Epsom,

- Forest Row,

- Godstone,

- Haywards Heath,

- Horley,

- Horsham,

- Hove,

- Leatherhead,

|

Printer repair:-

- Lingfield,

- Oxted,

- Partridge Green,

- Purley

- Redhill,

- Reigate,

- Sutton,

- Worthing

|

Operating hours

Monday - Friday

9.00am - 5.30pm

| Labour Costs

Call out from £30.00

SEE CALL OUT ZONES

On site Labour

FIRST HOUR £90.00

ADD HOURS £10/10 MINS

Workshop Labour £10/10 MINS |

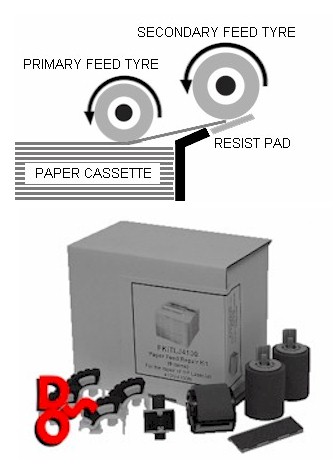

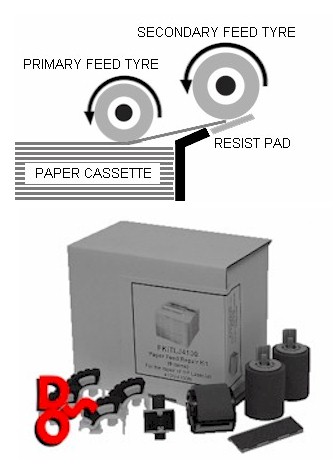

PAPER JAMS (WORN PAPER FEED TYRES)

SINGLE PRINT the Laser printer shows a jam, but no paper can be found in the printer. When this happens you will usually notice that there are no sheets of paper exiting the paper tray.

SINGLE PRINT the Laser printer shows a jam, but no paper can be found in the printer. When this happens you will usually notice that there are no sheets of paper exiting the paper tray.

MULTIPLE PRINTS the Laser printer shows a jam, multiple sheets of paper are found within the Laser printer with no noticeable reason for why the printer has jammed. Again when this happens you will usually notice that there are no sheets of paper exiting the paper tray.

The reason the machine stops and shows the jam indicator is because a sheet of paper has not reached the registration switch in a predefined time.

These jams occur due to a sheet, or the next sheet (multiple sheet feeding) not being fed from the paper tray. These jams are sometimes accompanied by a grey mark appearing on the top sheet of paper in the paper tray, the mark is usually in the centre of the paper about a inch in from the lead edge. The mark occurs when the primary paper feed tyre slips on the paper, when trying to feed the next sheet of paper (it wheel spins). This is usually due to either dirty paper feed tyres, old paper feed tyres or worn paper feed tyres.

First thing to do is clean the tyres, you can do this yourself, but care must be taken not to damage paper feed switches located around the tyres. You must also be careful because some machines tyres are fixed to a shaft and cannot be rotated. You may wish to call out an engineer to do this for you. If we attend site we will clean the paper feed rollers with a very weak solution of soap and water, this will resolve the issue the issue temporarily. Moistening the rollers will give them grip again, but as soon as they dry out then your problem will return. The only effective solution is to replace the rollers. When you replace the feed tyre this must be done as a set to include Primary, secondary and resist/separation pad.

If your machine is jamming or you suspect that you may require new paper feed tyres

Give us a call on 01293 537827 we can supply and fit paper feed tyres

for all makes and models of photocopier or laser printer

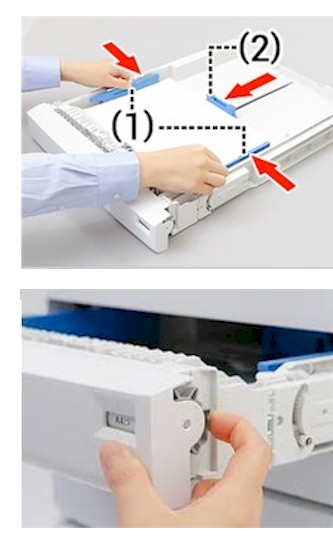

PAPER JAMS EXITING THE PAPER TRAY

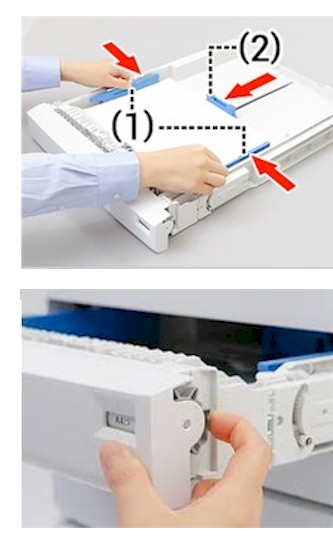

Another cause for a paper jams in the paper feed section, can initially seem to be due to worn paper feed tyres. BE CAREFUL if the paper tray guides are not set tight to the paper or the paper size indictor is not set to the correct size paper then a jam will occur.

Another cause for a paper jams in the paper feed section, can initially seem to be due to worn paper feed tyres. BE CAREFUL if the paper tray guides are not set tight to the paper or the paper size indictor is not set to the correct size paper then a jam will occur.

These jams happen because the machine has a set time ie 340 milli seconds to transport the paper from the cassette to the registration switch. If the rear paper guide has slipped back just 8mm then the machine will jam because this extra distance the paper needs to travel to get to the registration switch will exceed 340 milli seconds.

The paper guides move especially if a full tray of A3 paper is slammed shut, the jolt of shutting the tray will jar the rear paper guide back in the tray. SHUT PAPER DRAWS GENTLY.

Jams will also occur if the machine thinks that the paper is a different size to that installed in the tray.

Some machines use a manual dial like this picture, other machines use a setting input through the control panel. Be careful with A4 this usually has two settings for long edge feed (portrait) or short edge feed (landscape).

In long edge feed the laser printer is expecting a document 210 mm long and will allow a shorter time for the paper to pass the registration switch.

On multi-function printers check that the displayed paper size for the cassette matches the size and orientation of the paper in the cassette.

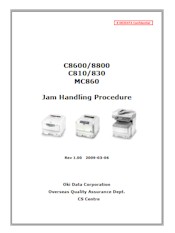

OKI 8 SERIES JAM HANDLING PROCEDURE

OKI have a comprehensive paper jam diagnosis document you can download here for the

- OKI C810, C830 Printers

- OKI ES8430 Printer

- OKI MC860, MC851, MC861, MC851+, MC861+

- OKI ES8460, ES8451, ES8461, ES8451+, ES8461+